OSSTEC

One Step Further

Knee implants combining innovative 3D-printed articulating surfaces with biomimetic cementless fixation for enhanced functionality, superior fixation, and a long-lasting bone foundation.

Why OSSTEC

Clinical Needs &

Future of Knee Implants

“Cementless Unicompartmental knee replacement offers advantages over cemented techniques, with improved workflows, survival, and clinical outcomes. OSSTEC's 3D printing technology enhances fixation, marking an exciting advancement in knee replacement surgery.”

Mr. Alex Liddle, DPhil FRCS(Orth)

Increasing Prevalence of Knee Osteoarthritis (OA)

0.0M

1.3 million people globally receive knee replacement surgery every year, with more and more people being treated younger.

High Long-term Failure Rate of Current Implants

0%

Existing implants see high failure rates in young patients and the leading cause of failure is loosening between the implant and bone.

Cementless Implants Fail Less

0%

Cementless implants reduce the risk of loosening by 50% and offer long-term biologic fixation without the need for cement in the body.

Partial Knee Replacements are Better for Patients & Providers

0%

50% of patients are suitable for partial knee replacements, which offer faster recovery and better outcomes for patients and are cost effective.

Our Technology

Innovation in Care

At OSSTEC, we have spent years pushing the boundaries of engineering and medical research to introduce a new generation of partial knee implant.

Cementless Fixation & Biomimicry

Built for Outpatient Care

Fully Additively Manufactured

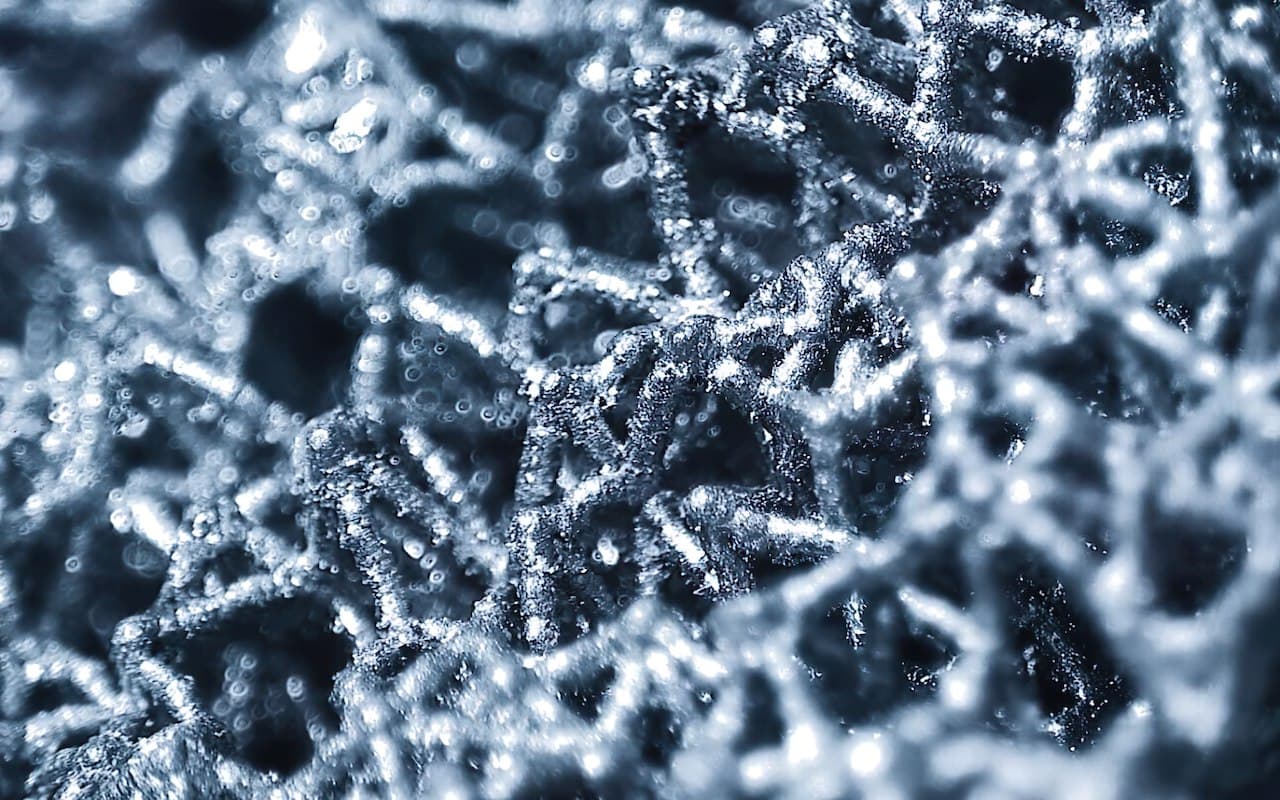

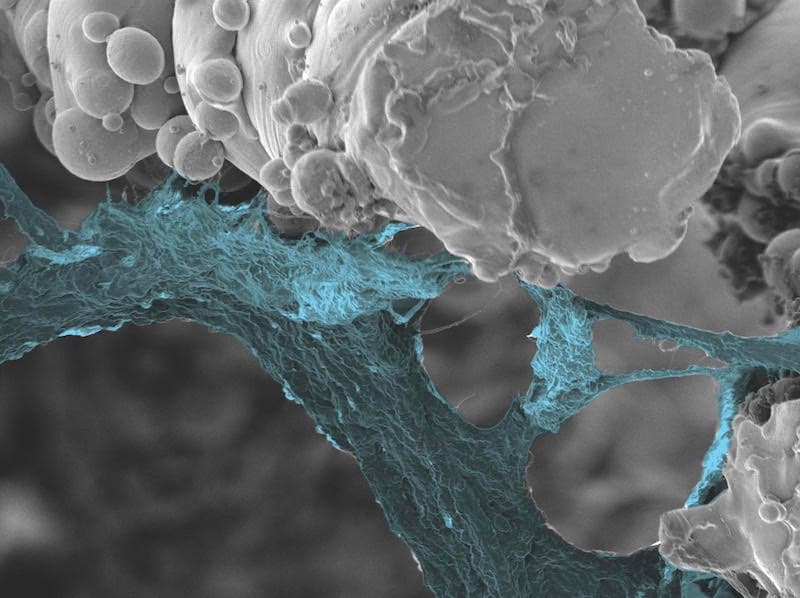

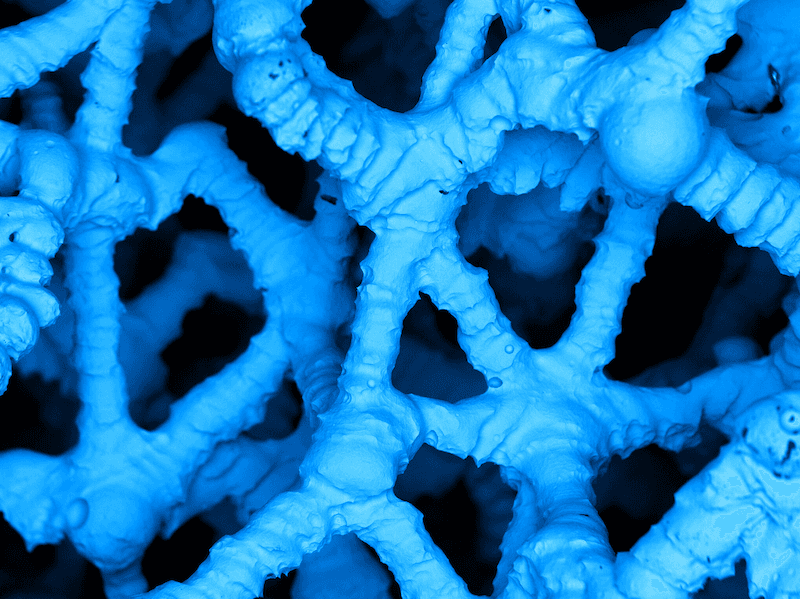

Our novel hybrid fixation features, combined with a 3D-printed porous lattice that mimics the trabecular structure of bone, ensures stable initial fixation while promoting natural bone ingrowth. This breakthrough design delivers revolutionary fixation without the drawbacks of bone cement..

Our cementless partial knee implant's advanced 3D-printed porous lattice enables immediate stability, allowing for quicker recovery and same-day discharge, making it ideal for outpatient care without the complications of bone cement.

Using next generation technology for next generation implants, additive manufacture allows for ultimate design freedom whilst reducing waste and costs per part.

Partners

We are collaborating with the UK's leading medical institutions and organisations to develop the next generation of orthopaedic implants.

Funding

£0.00M

secured in VC and grant funding.

News & Updates

Press Room

Keep up to date with all the latest news and updates from OSSTEC by following our LinkedIn page.